At Humber College, faculty members, researchers, and students engage in phenomenon-driven research, which focuses exclusively on an observable problem—with real, measurable consequences—and the solutions that come about through collaborative efforts with industry and community. A prominent example of phenomenon-driven research currently taking place at Humber is the project Robotic Painting Arm Development led by Principal Investigator Seyed-Youns (Younes) Sadat-Nejad, professor in the Faculty of Applied Sciences & Technology at Humber. The research project was awarded the Natural Sciences, and Engineering Research Council of Canada (NSERC) Engage grant ($25K) in November 2021.

Engage grants are designed to give innovative companies access to the knowledge, expertise and capabilities available at Canadian colleges. These grants are intended to foster the development of new research partnerships by supporting short-term research and development projects aimed at addressing a company-specific problem.

Industry Partner

Younes along with Co-Investigator Dr. Mehrdad Iravani-Tabrizipour, professor in Faculty of Applied Sciences & Technology, are collaborating with industry partner Mechatronic Diagnostics, a for-profit automotive diagnostic and repair centre.

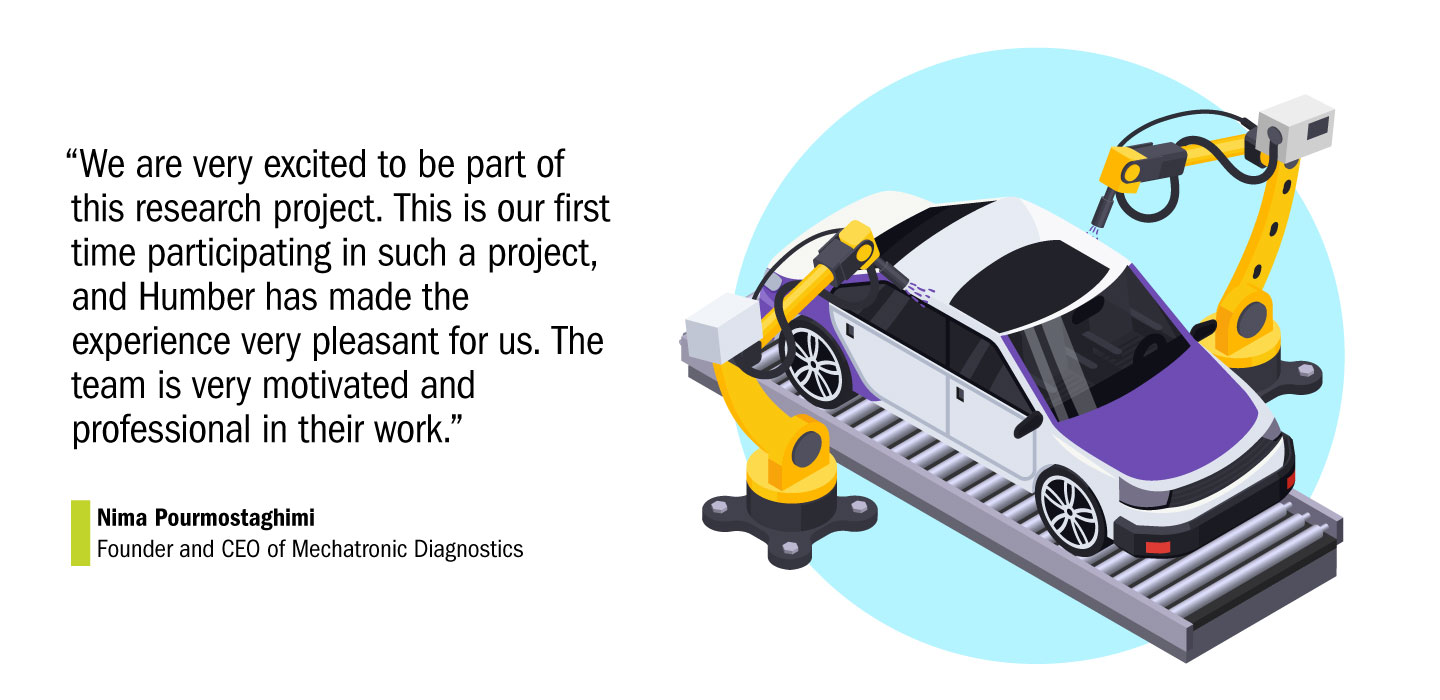

Nima Pourmostaghimi, founder and CEO of Mechatronic Diagnostics, shares the following about the collaboration:

“We are very excited to be part of this research project. This is our first time participating in such a project, and Humber has made the experience very pleasant for us. The team is very motivated and professional in their work.” —Nima Pourmostaghimi

Challenge

Mechatronic Diagnostics is challenged in finding expert painters and reducing the health hazards for its existing painters. The research project aims to develop an automated painting robotic system that is installable in the painting booth. The proposed solution will allow the industry partner to perform the operation of vehicle painting in their repair shop booth in an automatic manner, which will optimize the workflow and provide increased safety for employees.

Stages of the project

- Literature review in the commercially available type of robotic arm rail/gantry to be used, as well as 3D scan to the path-plan algorithm.

- Analysis of the literature review will inform the gantry design, 3D scanner model, and algorithm development approach.

- Analysis of booth requirements, and development of the rail-side/gantry system design based on the booth size and robotic arm model.

- Development of commands for the robotic arm to perform scanning with the scanner, and development of the algorithm that takes the scanner data as input and generates path-plan for painting.

- Testing and final prototype will help evaluate the performance of the robotic arm on scanning, generating paint paths from automatic scans, and painting over an unknown body. It is expected the solution will yield similar or better quality than a painting done by personnel.

Project leads

Younes Sadat-Nejad is a professor in Faculty of Applied Sciences & Technology, Humber College, a PhD Candidate at the University of Toronto, and CTO and co-founder of Veebar Tech, an IoT and AI-focused technology start-up. Younes has more than four years of teaching/research experience and two years of academic and industrial experience in the field of AI. His extensive experience in the development of technological systems, algorithm development, mathematics and data analysis will ensure the robustness of the project and development of the 3D to a path-plan algorithm.

Dr. Mehrdad Iravani-Tabrizipour is the Co-Investigator of the project. Dr. Mehrdad has more than eight years of teaching/research experience and two years of industrial experience in the field of Mechanical and Mechatronics Engineering. His experience in the development of robotic arm applications and algorithm development will ensure the functionality of the prototype and the design of the robotic system.

Student involvement

Two students—Gordon Ly and Mykhailo Leliseiev—from the Electromechanical Engineering Technology program at Humber College are research assistants for the project. The students will participate in the design of the robotic placement in the booth, development of the algorithms required for automation of the process and help build and test the device prototype.

Potential for impact

The automation of the painting process could result in an operation that could be done with the help of less-experienced workers. This eases recruitment, reduces the cost due to higher efficiency in painting, and requires less labour time. The environmental impact of the painting process will also be reduced as a result of a more efficient process. Moreover, the health risks associated with harmful coating chemicals will be significantly decreased as the painting process will be automated. Finally, the automation process can also be applied for non-vehicle painting, which provides the opportunity for the private sector to expand into other industries.

Get involved in research projects taking place at Humber today!

We acknowledge the support of the Natural Sciences and Engineering Research Council of Canada (NSERC). Nous remercions le Conseil de recherches en sciences naturelles et en génie du Canada (CRSNG) de son soutien.